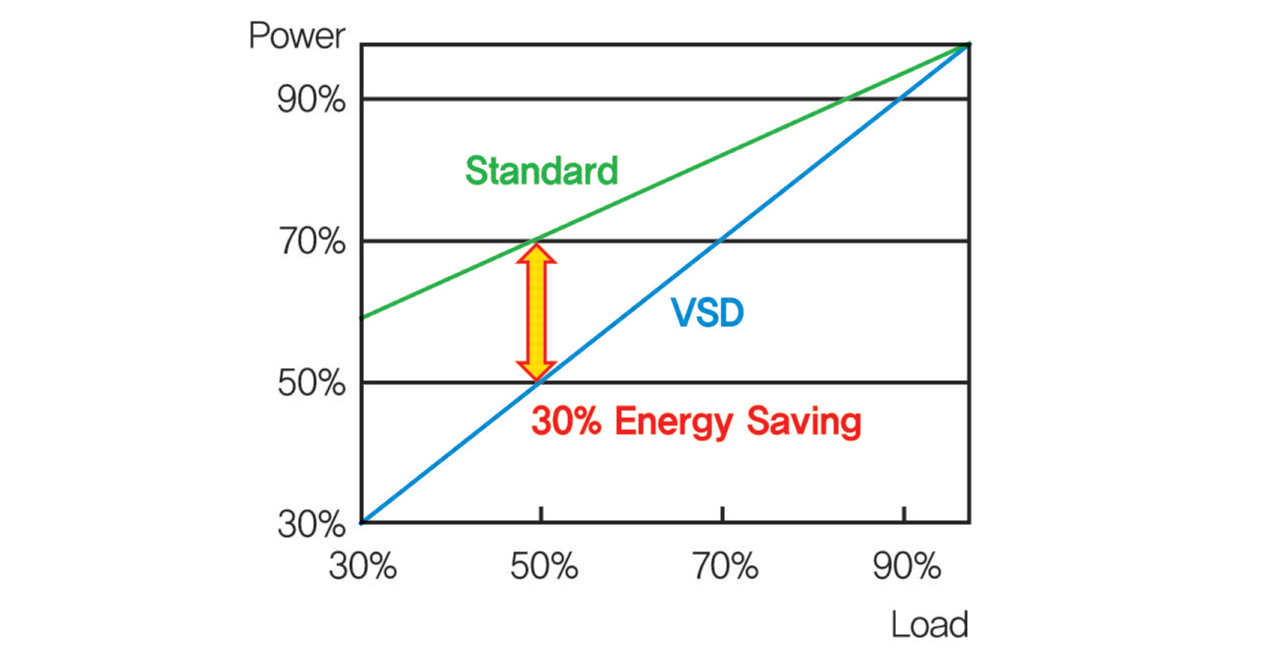

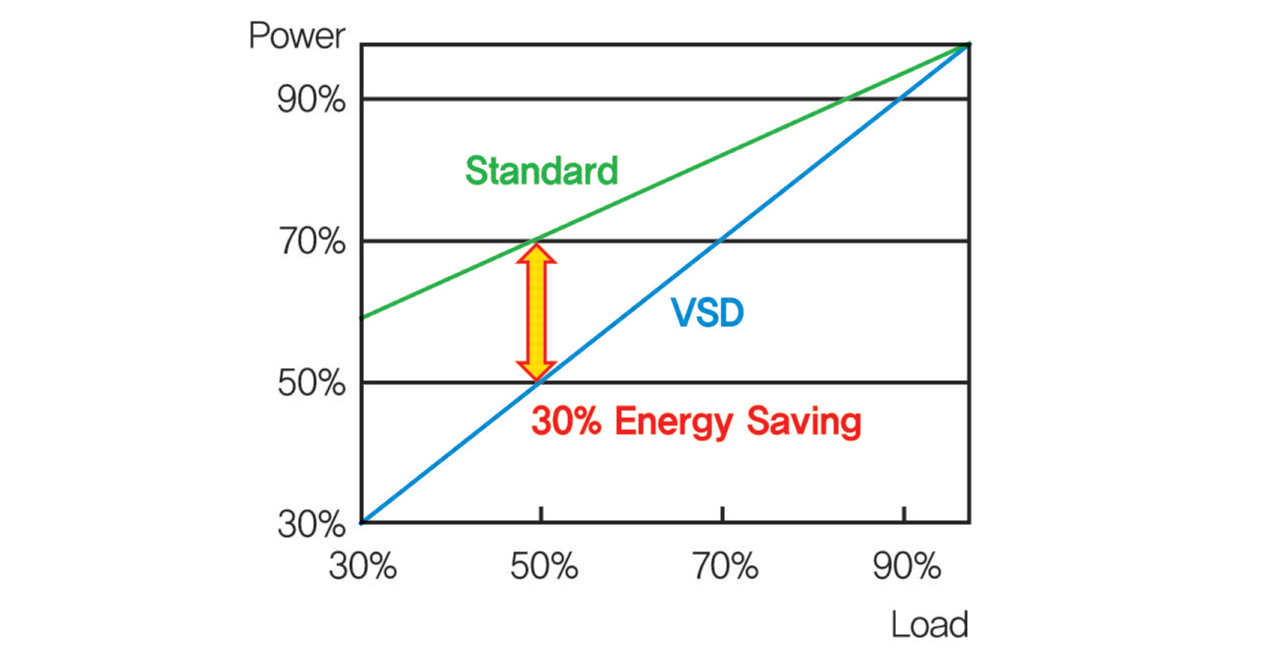

Up to 30% energy reduction through application of high efficiency inverter

Characteristics of AS V Series

Features & Benefits

- Technology verified by CE and UL certifications and high efficiency inverter with diverse ECM solutions

- Target pressure setting to reduce energy by up to 30%

- Free discharge pressure setting

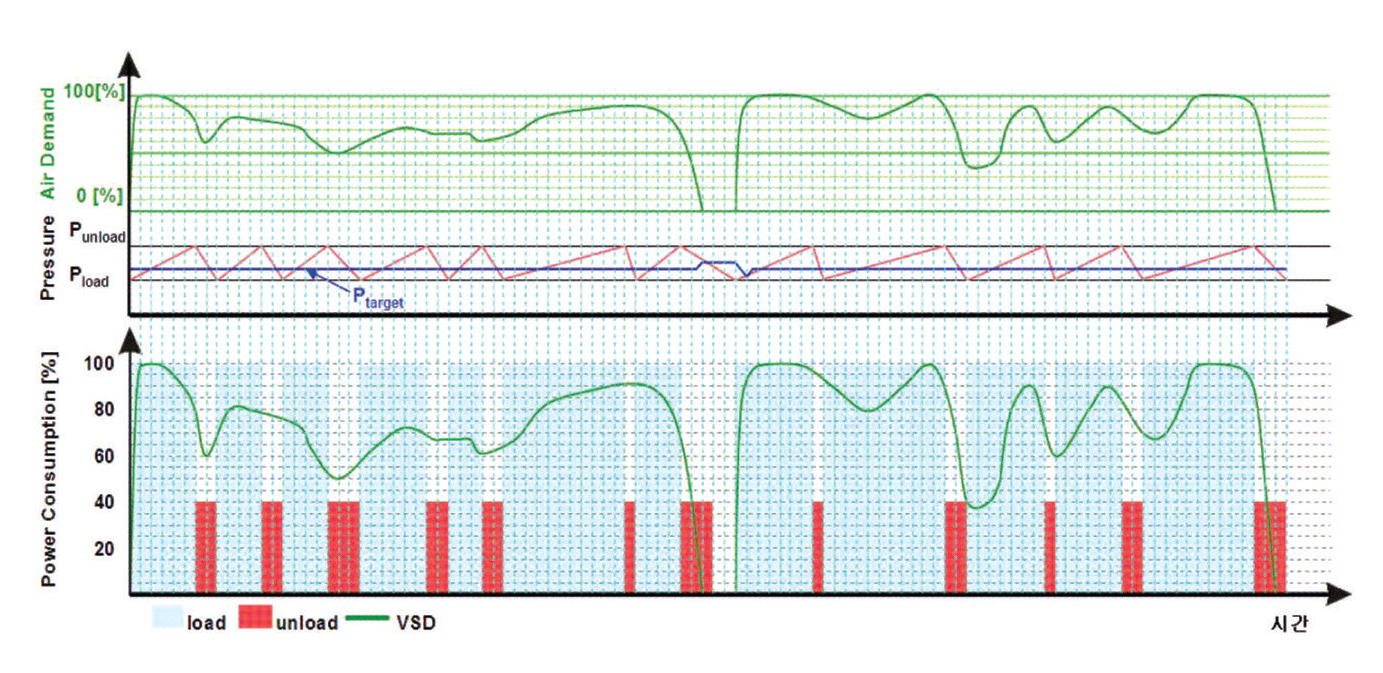

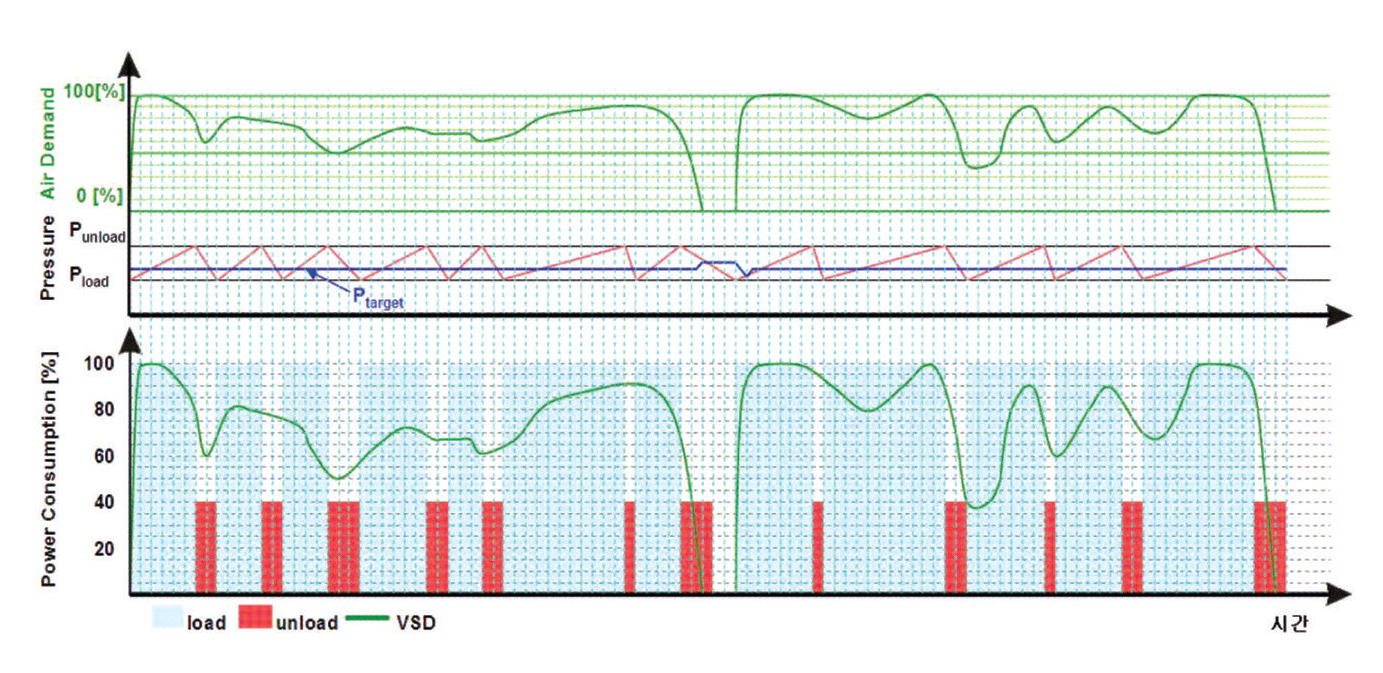

Examples of VSD operation

- Load rate: 76.7%

- Power load: 89.2%

- No-load power: 10.8%

- Power reduced by 10% under same pressure compared to the standard when VSD is used

- VSD stands for: Variable Speed Drive

Energy conservation effect of VSD Screw Compressor

- Power saved by no-load operation

: Free variation in speed quickly and precisely responds to ffluctuation in air demand of the system

- Compressed air required = prevents energy loss from production of unnecessary compressed air

Application of VSD Screw Compressor

- System with large change in compressed air demand

- System in which air demand pattern greatly changes with operation of production line

- System with large deviation of air demand between night / day production lines

- System with large deviation of air demand according to fluctuation in production volume for each month / season

- Large capacity facility that simultaneously operates multiple compressors

- Standard screw (=base load) + VSD screw (top load)

- System that requires constant pressure for consistent consumption of compressed air

Standard Specification of AS V Series

Compressor

Type |

Max.Working Pressure |

Capacity |

Motor Power |

Noise |

Dimension(LxWxH) |

Weight |

Air Outlet |

| kgf/㎠G |

psig |

㎥/min |

kw |

HP |

dB(A) |

mm |

kg |

A(B) |

| AS31V |

7.0

8.5

9.0 |

100

120

135 |

1.5~3.8

1.4~3.5

1.3~3.3 |

22 |

30 |

63 |

1500x1030x1350 |

775 |

25(1) |

| AS51V |

7.0

8.5

9.0 |

100

120

135 |

2.3~5.8

2.3~5.7

2.2~5.6 |

37 |

50 |

65 |

1660x1130x1607 |

1190 |

40(1 1/2) |

| AS76V |

7.0

8.5

9.0 |

100

120

135 |

4.2~10.4

3.6~8.9

3.4~8.5 |

55 |

75 |

72 |

2000x1210x1857 |

1780 |

50(2) |

| AS101V |

7.0

8.5

9.0 |

100

120

135 |

5.0~12.5

5.0~12.4

4.9~12.3 |

75 |

100 |

75 |

2000x1210x1857 |

1820 |

50(2) |

| AS151V |

7.0

8.5

9.0 |

100

120

135 |

8.3~20.7

8.1~20.3

8.0~20.1 |

132 |

175 |

78 |

3050x1470x2156 |

3080 |

65(2 1/2) |

| AS201V |

7.0

8.5

9.0 |

100

120

135 |

9.8~24.5

9.6~24.0

9.4~23.5 |

160 |

215 |

79 |

3200x1640x2156 |

3250 |

80(3) |

- Specifications are subject to change without prior notice due to remodeling of products, etc.

Introduction to Air Demand Analysis Device for Energy Reduction

Sequence of energy reduction project [SCADAR SYSTEM]

- 1. Dispatch of compressed air system engineer :

Determination of necessary conditions through on-side survey on the customer's air compression system and negotiation on details

- 2. Installation of air demand analysis device (SCADAR) :

Analysis on the current system and compressed air usage pattern of the customer

Data collected according to the configured cycle for at least 7 days and at most 14 days

- 3. Analysis on air compressor usage pattern :

Information collected by air demand analyzer is used to submit anlaysis data on actual usage or usage pattern of each air compressor

- 4. Precise diagnostics and recommendation of optimal product composition :

Consulting and data submission on expected reduction in power cost and investment recollection period when inverter air compressor is implemented

Air Demand Analysis Device

Air Demand Analysis Device

[ Air Demand Analysis Kit ]

- Actual amount of air use or type of use is analyzed at the site

- Optimal product composition recommended as appropriate for conditions of use

- Data submitted by presenting power saving effect from minimized power consumption

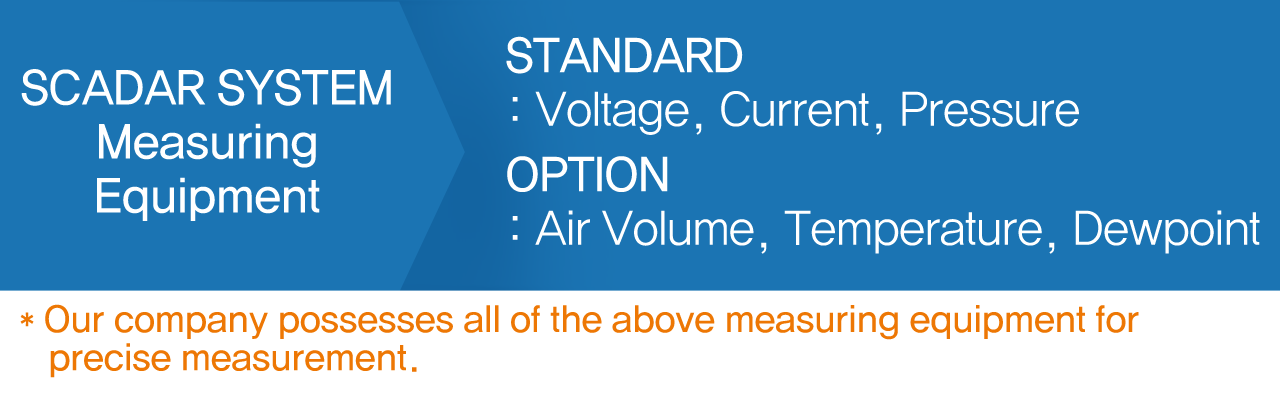

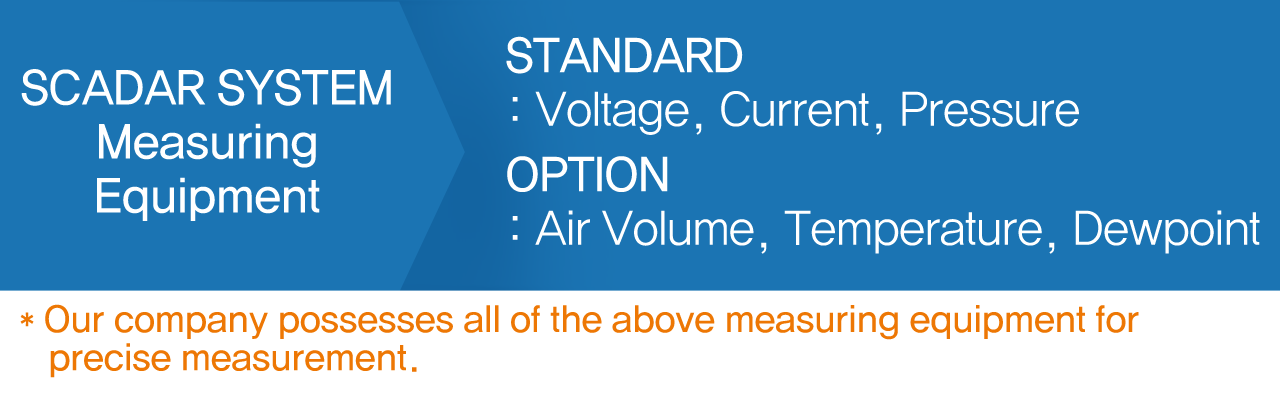

Components of SCADAR SYSTEM

Measurement Data

We select your compressed air and pressure based on accurate measurement data for each time period, providing a service for optimal compressed air system.

Pressure & Flow Data

Current, Voltage & Power Data

Energy Reduction Examples of Inverter Air Compressor

T Metal:manufacture of construction equipment parts [energy reduced by about 26%]

- Installed model : AS120V(2SET)

- Installation date : 2013. 01

- Energy reduction expected after installation of a 100-horsepower inverter compressor and operating number management system in an existing manufacture line (expected reduction rate over 15%)

Y Short Industry:painting and short industry [energy reduced by 15%]

- Installed model : AS101V (1SET)

- Installation date : 2013. 03

- Energy reduction expected after new installation of a 100-horsepower inverter compressor in an existing manufacture line and improvement on pipe leak (expected reduction rate over 20%)

S Industry:manufacture of machineries and gears [energy reduced by about 15%]

- Installed model : AS101V(1SET)

- Installation date : 2014. 02

- As a result of measuring energy consumption after installation of 100-horsepower inverter compressor and operating number management system in a new manufacture line, annual energy reduction of about 8,000,000 won was achieved

T Company:manufacture of automobile parts [energy reduced by 20%]

- Installed model : AS101V (2SET)

- Installation date : 2014. 04

- As a result of measuring energy consumption after installation of 100-horsepower inverter compressor and operating number management system in a new factory, annual energy reduction of about 11,000,000 won was achieved

Product List