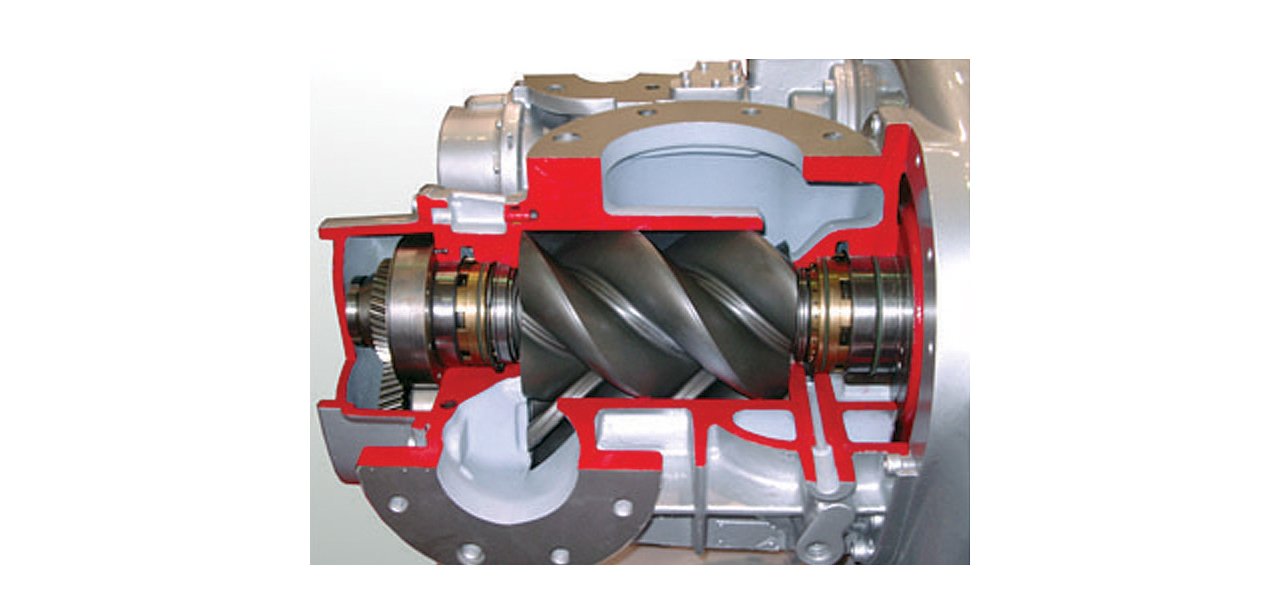

Oil free screw compressor of Kyungwon boasting highest performance

| Compressor Type |

Max.Working Pressure | Capacity | Motor Power | Noise | Dimension(LxWxH) | Weight | Air Outlet | |||

|---|---|---|---|---|---|---|---|---|---|---|

| kgf/㎠G | psig | ㎥/min | cfm | kw | HP | dB(A) | mm | kg | A(B) | |

| AF75 | 7.0 8.5 9.5 |

100 120 135 |

9.0 7.8 7.8 |

317 277 276 |

55 | 75 | 76 | 2300x1570x2090 | 2600 | 50(2) |

| AF100 | 7.0 8.5 9.5 |

100 120 135 |

12.2 10.6 10.6 |

431 375 374 |

75 | 100 | 78 | 2300x1570x2090 | 2800 | 50(2) |

| AF125 | 7.0 8.5 9.5 |

100 120 135 |

15.9 13.6 13.5 |

562 479 477 |

93 | 125 | 82 | 2700x1660x2350 | 3200 | 80(3) |

| AF150 | 7.0 8.5 9.5 |

100 120 135 |

19.5 16.0 16.0 |

688 566 565 |

110 | 150 | 83 | 2700x1660x2350 | 3250 | 80(3) |

| AF175 | 7.0 8.5 9.5 |

100 120 135 |

21.6 19.4 19.4 |

764 686 685 |

132 | 175 | 83 | 2700x1660x2350 | 3300 | 80(3) |

| AF200 | 7.0 8.5 9.5 |

100 120 135 |

26.0 25.9 22.9 |

917 915 810 |

160 | 215 | 83 | 2700x1660x2350 | 3350 | 80(3) |

| AF250 | 7.0※ 8.5※ 9.5※ |

100 120 135 |

32.8 29.4 29.3 |

1,158 1,038 1,036 |

190 | 250 | 84 | 3320x2150x2400 | 4250 | 100(4) |

| AF300 | 7.0 8.5 9.5 |

100 120 135 |

41.9 35.1 35.1 |

1,479 1,241 1,239 |

220 | 300 | 84 | 3320x2150x2400 | 4400 | 100(4) |

| AF350 | 7.0 8.5 9.5 |

100 120 135 |

45.7 41.8 41.8 |

1,613 1,478 1,476 |

260 | 350 | 85 | 3320x2150x2400 | 4650 | 100(4) |

| AF400 | 7.0 8.5 9.5 |

100 120 135 |

50.3 45.6 45.6 |

1,775 1,611 1,609 |

300 | 400 | 85 | 3320x2150x2400 | 4800 | 100(4) |

| Compressor Type |

Max.Working Pressure | Capacity | Motor Power | Noise | Dimension(LxWxH) | Weight | Air Outlet | |||

|---|---|---|---|---|---|---|---|---|---|---|

| kgf/㎠G | psig | ㎥/min | cfm | kw | HP | dB(A) | mm | kg | A(B) | |

| AF50V | 7.0 8.5 9.5 |

100 120 135 |

2~5.4 2~4.9 2~4.6 |

71~191 71~173 71~162 |

37 | 50 | 73 | 1900x1180X1960 | 1800 | 40(1 1/2) |

| AF75V | 7.0 8.5 9.5 |

100 120 135 |

4.5~9.0 4.5~7.8 4.2~7.8 |

159~317 159~277 148~276 |

55 | 75 | 76 | 2300x1570x2090 | 2650 | 50(2) |

| AF100V | 7.0 8.5 9.5 |

100 120 135 |

7~12.2 6~10.6 6~10.6 |

247~431 212~375 212~374 |

75 | 100 | 78 | 2300x1570x2090 | 2850 | 50(2) |

| AF125V | 7.0 8.5 9.5 |

100 120 135 |

9~15.9 8.5~13.6 8.2~13.5 |

318~562 300~479 290~477 |

93 | 125 | 82 | 2700x1660x2350 | 3300 | 80(3) |

| AF150V | 7.0 8.5 9.5 |

100 120 135 |

12~19.5 11~16.0 11~16.0 |

424~688 388~566 388~565 |

110 | 150 | 83 | 2700x1660x2350 | 3370 | 80(3) |

| AF175V | 7.0 8.5 9.5 |

100 120 135 |

14~21.6 13~19.4 13~19.4 |

494~764 459~686 459~685 |

132 | 175 | 83 | 2700x1660x2350 | 3460 | 80(3) |

| AF200V | 7.0 8.5 9.5 |

100 120 135 |

16~26.0 15~25.9 15~22.9 |

565~917 530~915 530~810 |

160 | 215 | 83 | 2700x1660x2350 | 3500 | 80(3) |

| AF250V | 7.0 8.5 9.5 |

100 120 135 |

18~32.8 17~29.4 16~29.3 |

636~1158 600~1038 565~1036 |

190 | 250 | 84 | 3850x2150x2400 | 4430 | 100(4) |

| AF300V | 7.0 8.5 9.5 |

100 120 135 |

22~41.9 20~35.1 20~35.1 |

777~1479 706~1241 706~1239 |

220 | 300 | 84 | 3850x2150x2400 | 4580 | 100(4) |

| AF350V | 7.0 8.5 9.5 |

100 120 135 |

26~45.7 25~41.8 24~41.8 |

918~1613 883~1478 848~1476 |

260 | 350 | 85 | 3850x2150x2400 | 4840 | 100(4) |

| AF400V | 7.0 8.5 9.5 |

100 120 135 |

30~50.3 28~45.6 27~45.6 |

1059~1775 989~1611 953~1609 |

300 | 400 | 85 | 3850x2150x2400 | 5010 | 100(4) |